In today’s rapidly evolving world of tobacco alternatives, electronic cigarette factories are at the forefront of innovation. These facilities are not only revolutionizing the way people perceive smoking but also setting benchmarks in production efficiency and product quality. Electronic cigarettes, with their advanced technology, offer users a customizable experience that traditional cigarettes can’t.

Cutting-edge Technology in E-cigarette Manufacturing

The journey of an electronic cigarette begins at the factory, where state-of-the-art machinery and skilled workers ensure each product is made to meet rigorous standards. With the keyword electronic cigarette factory in mind, it’s essential to examine how these factories leverage cutting-edge technology.

Automated Assembly Lines

One major innovation is the use of automated assembly lines, which significantly increase production speed while maintaining precision. These machines are designed to handle delicate components such as coils, batteries, and e-liquids, ensuring their safe and efficient assembly.

Quality Control Processes

Factories employ advanced quality control systems to monitor each step of the manufacturing process. Sensors and AI technology help detect defects or irregularities, guaranteeing that only top-notch products reach consumers.

Sustainability Practices in E-cigarette Production

Sustainability has become a significant concern for industries worldwide, and electronic cigarette factories are no exception. Many initiatives are focused on reducing waste and promoting eco-friendly practices.

Eco-friendly Materials

Manufacturers are increasingly using biodegradable materials for packaging, minimizing the environmental impact. This shift not only improves sustainability but also appeals to environmentally conscious consumers.

Energy-efficient Manufacturing

The factories utilize energy-efficient systems to reduce their carbon footprint. From solar panels to advanced HVAC systems, these measures significantly decrease energy consumption.

Innovations Driving Consumer Experience

The keyword electronic cigarette factory delves deeper into the core of user experience enhancements. Thanks to innovations in design and technology, consumers are now enjoying a more satisfying and personalized vaping experience.

Customizable Devices

Personalization is key in modern vaping. Electronic cigarette factories now produce devices that allow users to adjust temperature settings, nicotine levels, and even LED lighting effects to suit their preferences.

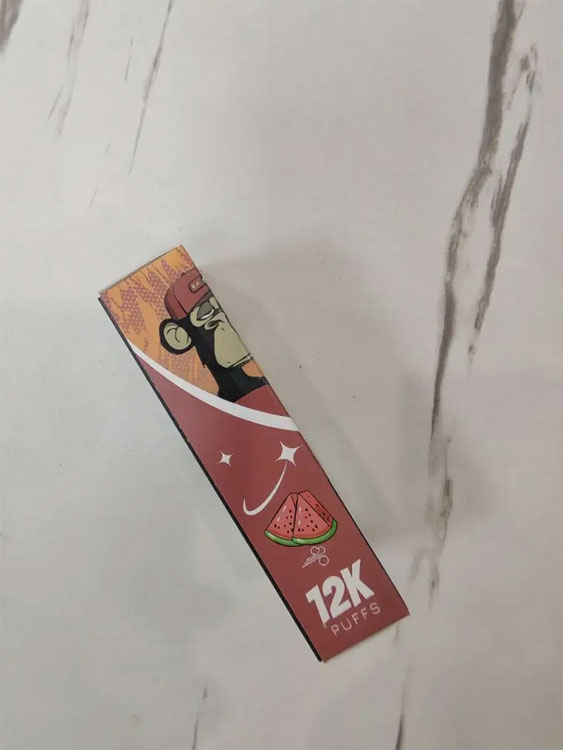

Flavor Variety

The range of e-liquid flavors has expanded considerably, offering users an array of choices that cater to diverse taste preferences—from traditional tobacco to exotic fruit blends.

Related FAQs

Q: What are the main components of electronic cigarettes produced in factories?

A: The primary components include a battery, atomizer, and e-liquid cartridge. Each component undergoes stringent quality checks to ensure optimal performance.

Q: How do electronic cigarette factories ensure product safety?

A: Factories implement rigorous quality control measures, including automated inspections and manual checks, to ensure every product is safe for consumer use.

Q: Are electronic cigarette factories environmentally conscious?

A: Yes, many factories are adopting eco-friendly practices, such as using biodegradable packaging and implementing energy-efficient manufacturing processes to reduce their environmental impact.